Izibani ze-LED ziphakeme kunezimbangi cishe kuzo zonke izikhundla. Kodwa, naphezu kwempilo yesevisi eshiwo, amanye amadivaysi ayasha ngisho nangaphambi kokuphela kwesikhathi sewaranti. Ungajahi ukuwalahla, amalambu angama-90% ashile angakhandwa.

- Idivayisi kanye nesimiso sokusebenza kwesibani se-LED

- Izifunda zomshayeli kanye nesimiso sokusebenza kwazo

- Ukuzinza kwamanje

- Ngokuqiniswa kwe-voltage

- Ngaphandle kokuzinza

- Ukuhlukana okuvamile

- Ukuhlukaniswa kwe-LED

- Inkohlakalo yabashayeli

- Ukunqunywa kwembangela yokungasebenzi kahle

- Ukuthola ama-LED angalungile

- Isibani se-LED saqala ukukhanya njenge-strobe

- Uma ama-LED eqinile

- Yini ezodingeka ukuze kulungiswe?

- Indlela yokuqaqa isibani se-LED?

- ukukhulula

- Ukushisa ngesomisi sezinwele

- Zenzele ngokwakho izibonelo zokulungisa izibani ze-LED

- Zenzele wena 220 V ukukhanda isibani se-LED

- Lungisa usebenzisa isibonelo sesibani se-ASD LED-A60, 11 W ku-chip SM2082

- Ungawathengisa kanjani ama-LED awonakele kanye namasha athengiswayo?

- Izinyathelo zokuphepha lapho ulungisa ama-LED angama-220 V

- Imibuzo ehlobene edumile

Idivayisi kanye nesimiso sokusebenza kwesibani se-LED

Ukuze ulungise isibani esiholelekile, udinga ukwazi kahle idivayisi yaso. Kungakhathaliseki ukuthi hlobo luni lwama-LED asetshenzisiwe, wonke amadivaysi okukhanyisa, kuhlanganise ne-filament, anesakhiwo esifanayo.

Isibani se-LED siqukethe izingxenye ezilandelayo:

- Ama-LED. Imvamisa, izibani ze-LED zine-SMD ne-COB chips. Ama-Diode ashintshwa kuphela afanayo. Uma ingekho into efanelekile, solder wonke ama-LED – kufanele afane.

- Umshayeli . Ibhodi lesifunda eliphrintiwe lingaphakathi kwekesi. Leli bhulokhi liyijeneretha yamanje. Umshayeli unokusebenza kahle okuphezulu kanye nebanga lokushisa elibanzi lokusebenza (-40….+70°C).

- I-Plinth. Ezibani ze-LED, zenziwe ngensimbi noma nge-ceramics. Ingenziwa futhi ngepulasitiki ekwazi ukumelana nokushisa. Ezibanini ezinophawu, isisekelo asithengiswa – lokhu kuvimbela i-oxidation yayo. Kunezinhlobo eziningana zamasokisi, ezibani zasendlini, imvamisa, kusetshenziswa iphinikhodi ne-threaded.

- Ibhodi lesifunda. Inama-LED kuyo. Izinto zebhodi ziyi-anodized aluminium alloy. Ngezinye izikhathi, ukuze kube lula, izindawo zama-diode zibalwe – ukuze zingaphambanisi ukulandelana.

- I-radiator. Ivimbela ukushisa ngokweqile kanye nokushiswa kwesibani ngaphambi kwesikhathi. Ezibani zebhajethi, isici senziwe ngepulasitiki. Ezingeni eliphezulu, kuvame ukuba nama-radiators ensimbi angenasici, ubukhulu bawo buncike emandleni ama-diode.

- Izakhi ze-Optical. Amalambu amaningi e-LED afakwe i-diffuser. Ikakhulukazi ipulasitiki ye-matte. I-diffuser, egxilisa ukukhanya okugeleza nge-engeli ethile, iyenza ifane ngangokunokwenzeka.

Ama-Diffuser angeziwe – ukuphepha okuphelele. Ngokungafani namaflask engilazi, awakwazi ukuqhuma, okwenza ingozi yokulimala kubantu.

Idivayisi kanye nesimiso sokusebenza kwesibani se-led:

- I-voltage yokuhlinzeka evela ku-cartridge inikezwa kumatheminali esisekelo, lapho izintambo ezimbili zidayiswa khona – ngazo i-voltage inikezwa okokufaka komshayeli, futhi ukusuka kuyo i-DC voltage iya ebhodini elinama-LED.

- Ukusabalalisa ukukhanya noma ukuvikela izingxenye zokuhambisa ekuthinteni komuntu, ibhodi elinama-LED limbozwe ngengilazi ekhethekile.

I-Filament uhlobo lwamalambu e- LED . Ngaphandle, zifana kakhulu nezibani ezijwayelekile ze-incandescent. Kodwa ngaphansi kwesibani seglasi akuyona i-tungsten filament, kodwa ama-LED abukeka njengemicu.

Izifunda zomshayeli kanye nesimiso sokusebenza kwazo

Ukuze ulungise isibani se-LED, kubalulekile ukuqonda ukuthi isici ngasinye sisebenza kanjani. Bonke abashayeli be-220V bangahlanganiswa babe ngamaqembu amathathu – ngokuzinza kwamanje / kwe-voltage futhi ngaphandle kokuzinza.

Eqinisweni, umjikelezo ozinzile kuphela ongumshayeli. Inketho yesibili ihambisana nokuqiniswa kwe-voltage, kunalokho iwumthombo wamandla womugqa oholayo. Isekhethi ngaphandle kokuzinzisa inhle ngoba iyona elula ukuyilungisa.

Ukuzinza kwamanje

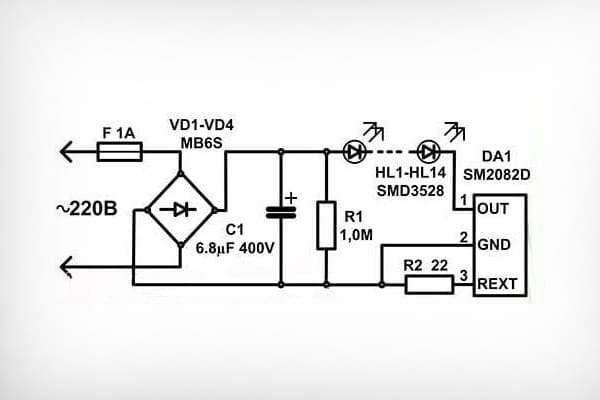

Kulo mjikelezo, kukhona isilawuli samanje esihlanganisiwe i-SM2082D. Nakuba inomshini olula, ithembekile impela futhi isezingeni eliphezulu, futhi okubaluleke kakhulu, ingalungiswa uma kunesidingo. Ngezansi umdwebo we-LED-A60 onomshayeli ogcwele:

Indlela isekethe isebenza ngayo:

- I-voltage esuka kunethiwekhi nge-F (fuse) ingena ebhulohweni le-diode VD1-VD4. Lapha iyalungiswa futhi idliwe ku-C1 (i-capacitor ebushelelezi). I-voltage elungisiwe (ehlala njalo) inikezwa kuma-LED futhi iphiniwe No. 2 ye-DA1 (microcircuit).

- Kusukela kokuphumayo No. 1 kwe-DA1, i-voltage ye-DC inikezwa kuma-LED. Inani lakamuva linqunywa inani lika-R2 (resistor).

- U-R1 unokuningi kakhulu ukumelana. Ivala i-capacitor futhi ayibambi iqhaza ekusebenzeni kwesekethe. Umsebenzi wayo ukukhipha ngokushesha i-capacitor lapho isibani sinqanyuliwe.

Uma lokhu bekungahlinzekisiwe, khona-ke lapho uthinta isisekelo, umuntu wayezothola ukushaqeka okunamandla kagesi, ngoba i-capacitor C1 ikhokhiswa ngesikhathi sokusebenza kwesifunda kuze kufike ku-300 V.

Ngokuqiniswa kwe-voltage

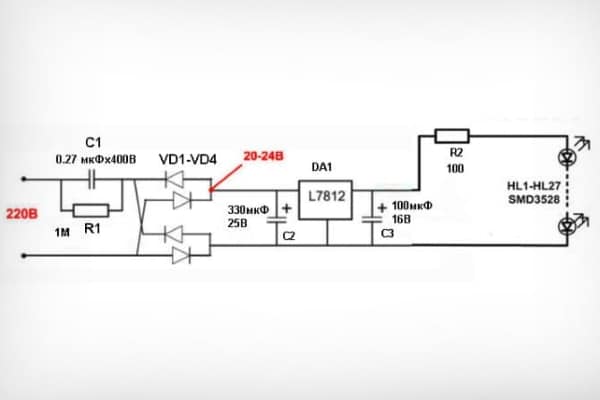

Lesi sifunda senza ukuzinza hhayi okwamanje, kodwa nge-voltage. Umfanekiso ongezansi uwumthombo wamandla wesibani esiholelekile:

Isebenza kanjani:

- I-voltage evela kunethiwekhi inikezwa ku-C1 (capacitor), eyehlisela cishe ku-20 V, bese iya ku-VD1-VD4. Lapha i-voltage iyalungiswa, ibushelelezi ku-C2 (i-capacitor) futhi idliwe kumlawuli we-voltage ohlanganisiwe.

- Ngaphezu kwalokho, i-voltage ishintshwe kabusha – kuya ku-C3 (capacitor), idlula ku-resistor ekhawulelwe yamanje engu-R2 futhi inikezwa kuma-LED.

Inketho ihluka kwedlule ngokuba khona kwesiphikisayo esinomkhawulo wamanje. Ingqikithi yesekethe yi-strip ye-LED enomthombo wamandla.

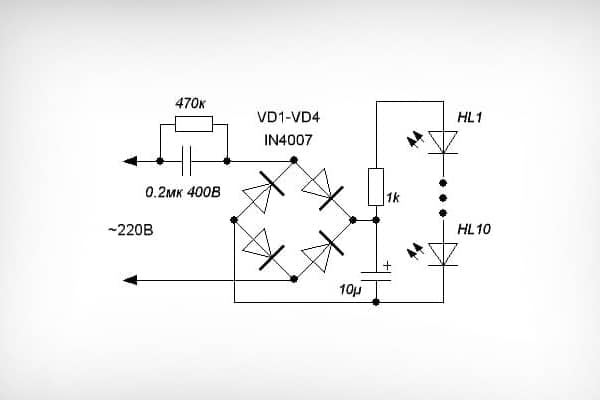

Ngaphandle kokuzinza

Umshayeli onjalo usetshenziswa ezibanini ezishibhile zaseShayina. Kodwa, nge-voltage evamile kunethiwekhi – ngaphandle kokwehla ngokuzumayo, lesi sifunda sisebenza kahle kakhulu. Ukuzinza kwamandla wamanje noma amandla kagesi akuhlinzekiwe lapha. Kukhona ukulungiswa kuphela kwe-voltage nokuyehlisela inani elidingekayo.

Indlela isekethe isebenza ngayo:

- Kukhona i-quenching capacitor, evalwa nge-resistor ukwandisa ukuphepha.

- I-voltage isetshenziswa ebhulohweni le-diode, bese ilungiswa ku-capacitor encane (cishe ama-microfarad angu-10) futhi, ngemva kokudlula ku-resistor-limiting yamanje, inikezwa kumjikelezo we-LED.

Isekethe, empeleni, ayiyena umshayeli. Ukuzinza akwenziwa lapha, ngakho-ke i-voltage ehlinzekwa kuma-LED incike kumapayipi amakhulu. Uma i-voltage ye-mains ingazinzile, ukukhanya kuzocwayiza.

“Abashayeli” abanjalo bavame ukutholakala ezibani zebhajethi. Uma i-voltage yamapayipi ijwayelekile, ngaphandle kokugxuma, isibani asicwayizi futhi singasebenza isikhathi eside impela.

Ukuhlukana okuvamile

Izibani eziholelekile ezisezingeni eliphakeme azivamile ukuphuka, awukwazi ukusho okufanayo ngabalingani abashibhile. Ukuphuka kwenzeka kubo, imvamisa ama-LED agqekeza noma umshayeli ehluleka.

Ukuhlukaniswa kwe-LED

Ezibani ze-LED, ama-LED axhunywe ochungechungeni. Ukukhishwa kwe-diode eyodwa kuxhunywe kokokufaka kwenye – isifunda silula kakhulu. Kodwa kwanele ukuba ikristalu elilodwa liphuke ukuze isibani siyeke ukuvutha.

Ama-LED awaqinisekisiwe ngokumelene nokutubeka, ngakho-ke uma isibani singashi, into yokuqala okufanele uyenze ukuwahlola. Kulula kakhulu ukwenza lokhu. Okudingayo i-multimeter.

Ungawahlola kanjani ama-LED ukuze ahlukanise:

- Hlola amakristalu. Ezisetshenziswayo zinombala okhanyayo ofanayo, amabala amnyama abonakala kuma-LED aphukile.

- Ama-LED awonakele. Sicela uqaphele ukuthi izinga lokushisa eliphezulu amakristalu alibekezelela ngaphandle kokulimaza izakhiwo zawo ngu +80°C. Sebenzisa i-soldering iron enamandla aphansi noma insimbi ukuze udilize.

- Esikhundleni sama-LED athengisiwe, ama-analogue asebenzisekayo we-solder ngokufaka i-flux ku-pad.

Ungahlola kanjani impilo yesibani nge-multimeter:

Isibani esilungiswe ngale ndlela sizosebenza, noma kunjalo, sizokhanya kancane kancane. Lolu khetho lusebenza uma kukhona amakristalu ayi-10 noma ngaphezulu ebhodini. Kwenzeka ukuthi amakristalu ashisiwe angashintshwa ngama-wire jumpers.

Ezibanini ezingama-220v, kusetshenziswa ama-LED ezinhlobo ezahlukahlukene – kukesi lepulasitiki, elingapakishwanga, kuma-ceramics obala, engilazini, isafire, noma umugqa wensimbi.

Inkohlakalo yabashayeli

Uma ngokubukeka kwawo wonke ama-LED eqinile noma enephutha kakade ashintshiwe, futhi isibani sisacishiwe, sekuyisikhathi sokudlulela ekuhloleni umshayeli. Umonakalo omkhulu ungabonakala ngokubukeka – ngokushintsha ukubukeka kwama-resistors noma ama-capacitors.

Uma kungekho monakalo obonakalayo kumshayeli, ucwaningo lwenziwa kusetshenziswa umhloli:

- Hlola zonke izakhi kuqala, bese amaphuzu e-soldering, njengoba othintana nabo bewohloka noma benyamalala ngenxa yokushintsha kwezinga lokushisa. Esimweni sokuqala, ukukhanya kuvuliwe futhi kuvaliwe, ekugcineni akusebenzi ngokuphelele.

- Ukuze unqume umonakalo ku-solder, yihlole ngokucophelela ekukhanyeni. Shisisa ngokucophelela izindawo ezinemifantu nge-soldering iron.

- Amabhuloho e-Diode awavamile ukubhidlika, ngakho ahlolwa okokugcina. Uma uthola i-diode ephukile, yehlise bese uhlola futhi. Uma ukwehluleka kuqinisekiswa, shintsha i-diode engalungile ufake efanayo, ubheka i-polarity.

Imiyalo yevidiyo:

Ukunqunywa kwembangela yokungasebenzi kahle

Kunezizathu eziningana zokuhluleka kwesibani se-led, ngakho-ke, ngaphambi kokuqhubeka nokulungiswa, kuyadingeka ukucacisa ukuthi kungani i-flicker noma ingashisi nhlobo.

Into yokuqala okufanele uyenze uma isibani se-LED singakhanyi ukusikhulula ku-cartridge bese ugoqa esinye (iholwa ngokuzikhethela) endaweni yaso. Futhi, uma ikhanyisa, khona-ke imbangela yokungasebenzi kahle isibani ngokwayo.

Ukuthola ama-LED angalungile

Ungahlola ukusebenza / ukungasebenzi kahle kwama-LED usebenzisa i-multimeter. Ishintshele kumodi yokuqhubeka futhi uhlole wonke ama-LED ngokulandelana. Ukuze wenze lokhu, sebenzisa ama-probe koxhumana nabo bekristalu ngayinye.

Ukuze useshe ama-LED aphukile, ungasebenzisa futhi ibhethri engu-3-4 V enaxhumana nabo abadayisiwe. Ngokubheka i-polarity, sebenzisa izintambo kuma-diode. Amakristalu anempilo azoshisa, kodwa aphukile ngeke.

Isibani se-LED saqala ukukhanya njenge-strobe

Uma isibani singacimi ngokuphelele, kodwa siyacwayiza, singabuye silungiswe.

Izizathu zokucwayiza kwezibani ze-LED:

- I-capacitor ebuthakathaka noma engekho. Inkinga ingaxazululwa ngokubeka isici esinamandla kakhulu. Uma i-voltage ye-capacitor ingu-100 V, futhi i-voltage ye-diode ingu-180 V, inani lokuqala kufanele lenyuke izikhathi ezingu-1.5-2.

Isixazululo sesibili senkinga ukuxhuma i-capacitor yesibili ngokuhambisana (ukuze kwandiswe ingqikithi namandla). - Ukushisa ngokweqile komshayeli. Isizathu ukungangeni kahle komoya. Isibani, ngenxa yokushisa ngokweqile, siqala ukucwayiza nokucwayiza, futhi lapho i-resistor yokukhawulela yamanje ihluleka, izocisha ngokuphelele.

Uma ama-LED eqinile

Uma wonke ama-LED asebenza, futhi isibani sivaliwe, cishe, umonakalo ubangelwa ukulimala kwezakhi zomshayeli – ama-resistors, ama-microcircuits, ibhuloho le-diode, njll.

Kulesi simo, kulula kumsebenzisi ojwayelekile ukuthenga isibani esisha, ngoba ukulungisa endala kuzodinga ulwazi oluthile, amakhono namakhono. Kodwa, ngaphambi kokulahla isibani, vula ibhodi ngama-LED bese ubheka ngaphakathi.

Ukuze uqaqa isibani, khipha i-silicone, qaqa izikulufu bese uqaqa izintambo “+/-“. Umhlangano ungaba koxhumana nabo abalayishwe entwasahlobo noma ku-jumper edayisiwe. Nguye ovame ukuvutha ngenxa yokungaxhumani kahle.

Yini ezodingeka ukuze kulungiswe?

Ukuze ulungise isibani esiholelekile, uzodinga ukukala nge-multimeter.

Futhi ukuze ulungise uzodinga:

- i-soldering iron yamandla aphansi, enethiphu elincanyana;

- ama-tweezers;

- abasiki bezintambo;

- ama-platypus;

- izingxenye ezisele – kuzodingeka zithengwe kuye ngohlobo lokuqhekeka.

Kuyinto efiselekayo ukuba nesibani esingasebenzi – singaba umthombo wemininingwane edingekayo.

Ama-Platypus abizwa ngokuthi ama-pliers amancane. Zinezimbambo ezinde, ezilungele ukubamba izingxenye ezincane. Eqinisweni, uma engekho ama-platypus, ungadlula ngama-tweezers.

Indlela yokuqaqa isibani se-LED?

Ukulungisa noma ukuguqulwa kwezibani ze-LED akunakwenzeka ngaphandle kokuhlakazwa kwazo. Le nqubo ayikwazi ukubizwa ngokuthi inkimbinkimbi, kodwa idinga ukunemba okuthile. Kubalulekile ukuthi ungalimazi noma iyiphi ingxenye yesibani. Ibhodi lesifunda eliphrintiwe lidinga ubumnandi obukhethekile.

Kunconywa ukudubula ukuhlakazeka kwesibani kuvidiyo ukuze ungaphambanisi ukuhleleka okuphambene kokusebenza.

ukukhulula

Isibani se-LED siyidivayisi ebuthakathaka, ngakho-ke sihlakaze ngokucophelela, ngaphandle kokusebenzisa amandla namathuluzi abukhali lapho ungenza khona ngaphandle kwawo.

Inqubo:

- Susa i-diffuser dome. Ukuze wenze lokhu, thatha isibani sokukhanyisa emaphethelweni ngezandla zombili futhi ngokunyakaza okujikelezayo ngokucophelela kwehlukanisa ingxenye engaphezulu emzimbeni. I-bonding sealant incane kakhulu, ngakho ngokuvamile ayithathi umzamo omkhulu.

- Hlukanisa ipuleti elinama-LED emzimbeni ngokukhulula amabhawodi okulungisa. Sebenzisa ama-screwdrivers ohlobo olunembayo olukhethekile.

- Nqamula i-mounting plate ku-heatsink. Sebenzisa into ebukhali, eyisicaba, njengama-tweezers. Gcoba kancane unqenqema lwebhodi bese ulususa ngokuphelele.

- Khipha izindawo zokuxhumana zezintambo zamandla futhi ekugcineni uhlukanise ibhodi ngama-diode kwezinye izingxenye.

- Hlukanisa isisekelo nerediyetha ngokuzungezisa. Beka zonke izingxenye zesibani etafuleni bese uqala ukulungisa.

Ukushisa ngesomisi sezinwele

Lolu khetho lufanele izibani ezinengilazi ewugqinsi. Isomisi sezinwele zokwakha sikuvumela ukuthi ushise umzimba wesibani ekushiseni okufunayo – lena yindlela kuphela yokukhipha ingilazi enamathiselwe kusisekelo se-cylindrical.

Ngenxa yomoya oshisayo, izingxenye ezishisayo ziyakhula futhi okunamathelayo okubambe ingilazi kuba nokunwebeka. Ngemuva kokushisa, isibani singahlakazwa kalula ezingxenyeni zaso.

Ividiyo yokuthi ungaqaqa kanjani isibani se-e27 LED:

Zenzele ngokwakho izibonelo zokulungisa izibani ze-LED

Ngaphambi kokuqhubeka nokulungiswa kwezibani ze-LED, kuyasiza ukucabangela le nqubo ngezibonelo ezithile. Azikho kuphela izinguqulo eziningi zezibani eziholelekile, kodwa futhi nokuphuka kwazo.

Izibani ze-LED zingaba phakade uma wenza ama-LED angasebenzi ku-100 noma i-120% yamakhono awo, kodwa ngo-50-70% – lokhu kuzonciphisa izinga lokushisa futhi kuvimbele ukushisa, ngenxa yokuthi izibani eziningi ze-LED zihluleka.

Zenzele wena 220 V ukukhanda isibani se-LED

Umshayeli, okuthi ku-80% wamacala abangele ukuphuka, akakhiwe esibani. Ingaqukatha ama-LED wodwa, futhi idivayisi yokusimamisa yakhiwe ku-luminaire.

Uma umshayeli wenziwa ngokwehlukana, ukulungisa kulula ukukwenza. Kwanele ukushintsha isibani futhi uqinisekise ukuthi inkinga ikuyo. Uma kungenjalo, i-stabilizer iphukile. Ezibani ezinomshayeli owakhelwe ngaphakathi, isimo sinzima kakhulu.

Inqubo yokulungisa isibani seqhwa ngomshayeli:

- Vula i-heatsink ngokuphambene newashi ukuze uqaqe isibani.

- Susa umshayeli. Khalisa wonke ama-LED, ibhuloho le-diode kanye ne-microcircuit ngesihloli.

- Awukwazi ukusebenza nezingxenye ze-SMD ngensimbi yokunamathisela, ngakho-ke sebenzisa umshini wokomisa izinwele kanye nesiteshi sokunamathisela. Akuwona wonke umuntu onalawa madivayisi, ngakho-ke udinga ukwazi ukuthi ungakwenza kanjani ngaphandle kwawo.

- Ngemuva kokuhlanganisa i-microcircuit kanye nebhuloho le-diode, gcoba othintana nabo ngokunamathisela okukhethekile bese ukufudumala. Lokhu kuzokuvumela ukuthi kamuva ufake izakhi ezincane endaweni futhi uzidayise ngokucophelela.

- Qala nge-microchip. Izingxenye ezifanayo zithengiswa esitolo se-inthanethi saseShayina esaziwayo ngama-ruble angu-50-80. ucezu. Namathisela i-chip ku-paste, uyibambe bese uyithumela.

- Okulandelayo ukujika kwebhuloho le-diode. Ungakwazi futhi ukuthenga le ngxenye kumasayithi Chinese.

- Solder umshayeli oqediwe uyibeke esisekelweni. Unezintambo ezimfishane kakhulu, ngakho zakha. Lokhu kuzogwema ukudiliza i-plinth, egoqwe ebhokisini lepulasitiki.

- Solder olunye uhlangothi lomshayeli ebhodini lesifunda eliphrintiwe elinama-LED. Into esemqoka akuyona ukuhlehlisa i-polarity. Ngokuvamile, izigxobo zikhonjiswe ebhodini kanye nomshayeli – gxila kuzo.

- Hlola ukusebenza kwesibani. Kodwa, uma ungenalo ulwazi lomsebenzi kagesi, ungakwenzi lokhu ngenkathi isibani sihlakazwa – kukhona ingozi yesifunda esifushane kanye nokushaqeka kukagesi.

Ividiyo yokulungisa isibani se-LED:

Lungisa usebenzisa isibonelo sesibani se-ASD LED-A60, 11 W ku-chip SM2082

Namuhla, izibani ezinamandla eziholayo zisetshenziswa, lapho abashayeli behlanganiswa khona kuma-microcircuits e-SM2082. Okulandelayo yisibonelo sokulungisa isibani esasicisha ngezikhathi ezithile siphinde sikhanyise. Ukuxilongwa kokuqala – ukuthintana kabi.

Inqubo:

- Sebenzisa ummese ukuze ukhiphe futhi ususe ingilazi ehlakazayo.

- Hlola i-chip ye-SM2082. Uma ungazange ukhombe iziphambeko ku-soldering kanye namathrekhi aphukile, susa ibhodi. Ukuze wenze lokhu, nquma i-silicone bese uphonsa ibhodi nge-screwdriver blade.

- Ukuze ufinyelele kumshayeli, yikhiphe ngokushisa othintana nabo nge-soldering iron – kokubili ngesikhathi esisodwa, bese uyihambisa kwesokudla.

- Ngakolunye uhlangothi lwebhodi lomshayeli kukhona i-capacitor engu-400 V. Ngakolunye uhlangothi, kukhona ibhuloho le-diode kanye nama-resistors amabili. Ukuze uqonde ukuthi yiliphi ibhodi elingenakho ukuxhumana, lixhume nge-polarity – izintambo ezimbili.

- Thepha amabhodi ngesibambo se-screwdriver. Thola ukuthi iphutha likuphi – koxhumana nabo bezintambo, kuma-capacitors, ekuxhumaneni kwe-terminal ephakathi kwesisekelo.

- Uma othintana naye olimele etholakala, yigcobe nge-flux futhi uyidayise futhi.

Ungawathengisa kanjani ama-LED awonakele kanye namasha athengiswayo?

Ukuze usebenze nama-LED, kufanele ukwazi ukudambisa futhi ube nawo wonke amathuluzi adingekayo kulokhu. Ama-diode e-SMD awanazo izinto eziphethe njengamanje. Kunalokho, kunamaphedi okuxhumana akhethekile ebhodini. Ukuze usebenzise i-soldering sebenzisa i-soldering iron enamandla angu-12 watts.

Ukuze udale ama-LED uzodinga:

- ama-tweezers;

- ucezu;

- i-flux;

- i-soldering iron;

- umbambi.

Ungayithengisa kanjani i-LED kusuka kusibani se-LED ngensimbi ye-solder:

- Susa ibhodi le-aluminium ngokuhlukanisa indlu yesibani kusuka emthunzini wesibani.

- Hlola wonke ama-diode ngomhloli.

- Letha i-burner ngemuva kwebhodi imizuzwana engu-3-5. Nqamula i-diode lapho i-soldering ixega.

- Ngaphambi kokuba isisekelo siphole, faka ithonsi ye-flux kuphedi yokuxhumana bese ufaka i-diode phezulu, ucabangela i-polarity.

- Shisisa isisekelo futhi bese ucindezela kancane kukristalu. Bamba i-diode kuze kube yilapho “imilenze” igxiliwe ngokuphephile ku-solder.

Imiyalo yevidiyo:

Izinyathelo zokuphepha lapho ulungisa ama-LED angama-220 V

Lapho ulungisa izibani ze-led, kubalulekile ukugcina izinyathelo zokuphepha zikagesi eziyisisekelo. Lokhu kuzovimbela ukushaqeka kukagesi nokulimala.

Imithetho yokuphepha:

- Zonke izilinganiso kanye ne-soldering kufanele zenziwe kuphela kumabhodi angenawo amandla.

- Ungashiyi i-soldering iron ingagadiwe.

- Gqoka izibuko zokuzivikela (kunengozi yokuqhuma kwe-capacitor).

- Susa i-cap ngamagilavu afakayo (kukhona ingozi yokusikeka ngama-splinters).

- Yenza umsebenzi endaweni engenawo umoya, njengoba ukuhogela umhwamuko we-rosin kuyingozi empilweni.

Imibuzo ehlobene edumile

Nansi eminye imibuzo evamile mayelana nokulungisa izibani ze-LED. Lawa alandelayo:

- Kungani kuvunyelwe ukufinyeza amatheminali ama-LED ashile kumalambu e-LED? Umshayeli welambu le-led, ngokungafani nokunikezwa kwamandla kagesi njalo, ukhiqiza inani lamanje elizinzile ekuphumeni, hhayi i-voltage.

Ngakho-ke, kungakhathaliseki ukuthi ukumelana nomthwalo (ebangeni elinikeziwe), i-current izohlala njalo, okusho ukuthi ukwehla kwe-voltage ku-diode ngayinye kuzofana. - Iyini impilo yesevisi yesibani esilungisiwe, futhi singayandisa kanjani? Ayikho impendulo eqondile yalo mbuzo. Abantu asebezilungisele ama-ice lamps bebodwa bathi sebenonyaka nesigamu besebenza. Asikho isiqinisekiso sokuthi enye i-LED ngeke iphele ngenxa yokushisa ngokweqile.

Ngokuqinisekile, umenzi akafuni ukwenza izibani “zaphakade”, njengoba lokhu kuzothinta kabi umsebenzi wamabhizinisi abo.

Iningi lokuphazamiseka kwezibani ze-LED zingalungiswa ngesandla. Ukuze wenze lokhu, udinga ukuqonda kahle idivayisi yesibani kanye nesimiso sokusebenza kwayo. Ngokufunda ukulungisa ama-led-device, ungonga imali eningi ekuthengeni kwawo.