The power supply for the LED strip is the most important element for organizing effective lighting. You need to familiarize yourself with the principle of its operation and the main criteria for choosing, as well as learn how to properly connect the device to the LED strip. These and other important points are discussed in the article.

- General device requirements

- Criterias of choice

- Voltage conversion method

- Cooling system

- Execution

- Output voltage

- Power

- Additional functions

- Types of power supplies for LED strips

- Leaky

- Sealed

- Semi-hermetic

- Connecting the LED strip to the power supply

- Connection polarity

- Wire section selection

- Choice of switching circuit

- The difference between a power supply and an LED driver

General device requirements

LEDs are efficient and reliable devices. Manufacturers guarantee a long service life of these devices – 50 thousand hours or more. This means that the power supplies for them should serve for a long time and reliably. The main requirements for these devices:

- Energy Efficiency . The production of LEDs is primarily the introduction of energy-saving technologies. To maintain the efficiency of the LED lighting system, the power supplies must also be of adequate efficiency.

- Electromagnetic compatibility . The power supply in the LED lamp is, in fact, the only source of electromagnetic interference. Depending on what production parameters it will have, these will be the indicators of the general electromagnetic compatibility of the lamp.

- Electrical safety . The electrical safety of the LED lighting system is completely dependent on how safe the design of the power supply is in this respect, because it is the only device to which a 220V power supply is connected. The device must be reliably protected from short circuits and overheating.

- Power supply behavior . The lighting parameters of LED lamps are affected by the characteristics of the current passing through the LED. If it is changeable in time or pulsating, then you should not count on high quality lighting.

Criterias of choice

The choice of device must be treated carefully, focusing on reliable manufacturers. Inexpensive, low-quality devices can end up being expensive and create high-frequency noise problems that interfere with other equipment. When buying, it is important to know the total power of all sections of the tape (the voltage is known – 12 volts), to accurately select the design and type of the cooling system, and also pay attention to the parameters below.

Voltage conversion method

This setting depends on the device type:

- Transformer power supplies are reliable and have a simple circuit. The transformer converts 220 volts to 12 at one frequency. With the help of a rectifier, a sinusoidal current is converted into a direct one. Among the disadvantages: bulky and heavy weight, significant raw material costs in production, poor efficiency.

- Switching power supplies are devoid of all these disadvantages. They are distinguished by a low price, almost 100% efficiency, resistance to voltage fluctuations. However, such blocks have a more complex scheme, and the design itself, in the event of failure, is practically beyond repair.

Cooling system

It can be active or passive. In the first case, cooling occurs with the help of a fan, in the second, excess heat is removed naturally.

If the tape power is small, it is not advisable to buy a power supply with a fan. It will create unnecessary noise and require regular maintenance.

Execution

Power supplies are:

- Open (interior) . For their installation, dry residential, as well as well-ventilated rooms are most suitable.

- With closed body . They are usually installed where shocks or vibrations occur during operation.

- With sealed housing . In this version, they are suitable for conditions where humidity is high.

Properly selected type of device will increase the life of the lighting system.

Output voltage

The LED strip can have a voltage of 12, 24, 36 volts, controlled by SPI – 5 volts. These characteristics must be indicated on the device itself, as well as on the packaging. The voltage of the light source and the output voltage of the PSU must match. On sale there are power supplies equipped with a smooth voltage adjustment at the output. They are effective when a voltage compensator or non-standard voltage is needed in long wires. If you need to power sources that have different voltages, the best choice would be to purchase a power supply that is equipped with a channel complex, each of them delivering a different voltage.

Power

It is determined by the voltage and length of 1 meter (the indicators should be multiplied). The voltage can be found on the packaging, and the length is selected by the user. For the normal functioning of the tape, the obtained indicators need to be increased by an average of 40% – this will be the power reserve. Let’s look at an example. For each meter of LED strip, 15 watts are needed. To organize the backlight, 3 meters of tape are required. We calculate the power by simple multiplication and get 45 watts. Adding a margin, we get 58.5 watts. (45×1.3). In the absence of a power supply unit with just such a power, we choose an option that is closer to this indicator.

It happens that only the current strength is indicated on the packaging. Power in this case is determined by multiplying volts by amps.

Additional functions

12 volt power supplies are:

- conventional (mainly for food);

- equipped with a timer;

- equipped with a built-in dimmer;

- with controller (RGB tape);

- with remote control system;

- with dimmer and remote control.

The more additional features, the higher the cost of the device.

Types of power supplies for LED strips

The consumer is offered a wide selection of ready-to-use devices in various variations. They vary depending on the material used and the level of weather protection.

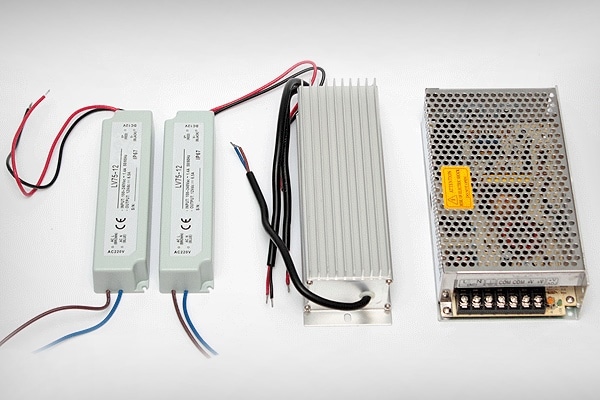

Leaky

Inexpensive, 12 V, but the most popular PSUs. They are intended, as a rule, for installation only in enclosed spaces and vehicles. They are considered the most suitable for mounting on suspended ceilings. The power of such power supplies is low – within 75 watts. In this regard, it is often necessary to install several power supplies in a room. The downside of these devices is poor protection from moisture and dust, moreover, they are not very attractive in appearance.

Sealed

Well suited for outdoor work, not afraid of high humidity and other adverse conditions. These appliances are great at dissipating heat. The case is well sealed, which is ensured by aluminum or plastic material. In rooms with high condensate, metal is most often used, which has greater strength and reliability, and a good heat dissipation. Such devices weigh more, which is their main disadvantage.

When installing facade lighting, it is best to buy power supplies in a metal case.

The plastic case is more compact, attractive in appearance, and weighs little. However, it also has significant drawbacks: it does not remove heat well, it is limited in power – no more than 100 W, and is more expensive.

Semi-hermetic

More versatile and can be installed both indoors and outdoors. Are characterized by degree of protection of IP54. Often used for mounting LED lighting under awnings and in kitchens.

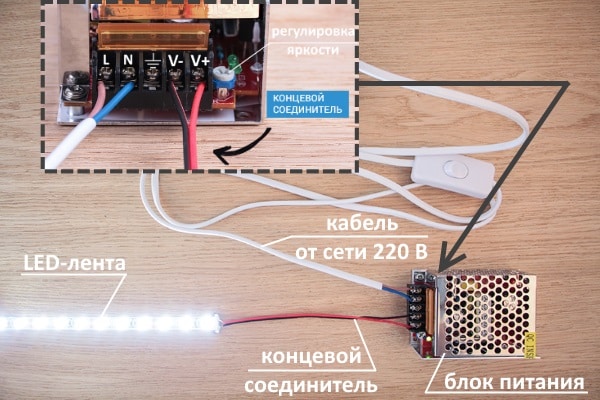

Connecting the LED strip to the power supply

The procedure consists of solving three main points:

- polarity detection;

- selection of the wiring section;

- schema selection.

Let’s consider them in more detail in order to do everything quickly and without any problems.

Connection polarity

Any 12-volt power supply is equipped with terminals that have opposite signs “+” and “-“. When the terminals are replaced with wires, they are marked with a different color. For the most part, the red wire corresponds to the plus, but the minus can be colored blue or black. In the same way, the wires of the LED strip are marked. You need to connect accordingly: plus – to plus, minus – to minus.

Wire section selection

A distinctive feature of LED strips is their relatively high power at low voltage. It is with this that the need for a large current is connected. For example, if a 70 W incandescent lamp requires a current of 300 mA, then an LED strip with the same power will require 7 A. When connecting an LED strip, you need to take responsibility for selecting the wiring section.

It is a mistake to assume that the cross section must necessarily be the same as that of the wires coming out of the power supply. This leads to a quick breakdown of the lighting device.

To connect the tape to the PSU, a wire with a cross section of 1.5 square meters is quite suitable. mm, since the power consumption of LED strips is relatively small.

Choice of switching circuit

To do it correctly, you need to consider the length and type of LED strip. For serial connection, small strips (maximum 5 meters long) are suitable for the power side. We connect the plus of the LED device to the plus of the power supply, and the minus to the minus. If you have an

RGB tape , then you should install the controller between the tape and the power supply. If it is necessary to connect several LED strips, the total length of which is more than 5 meters, a parallel circuit is used. Attach the segments to the power supply, but they do not need to be connected to each other. RGB is required for normal operation of 1 controller per 10m tape. If the power allows, two controllers can be connected to one 12 V unit. Details on the correct connection of LED strips are described in

this article . Watch the video that shows how to properly connect the power supply to the LED strip: https://www.youtube.com/watch?v=WA07cYPxYD0

The difference between a power supply and an LED driver

As a rule, with the help of a conventional PSU, a constant stabilized voltage is provided at the output, which is not affected by surges in the input mains voltage and fluctuations in current consumption. The power supply of the LEDs in most cases is carried out by a block that provides a constant current at the output. It’s called a driver. So it would be correct to say:

- stabilized current source – driver;

- constant voltage source – power supply.

When using a driver, there is no need to lower the voltage, since there is no danger that the LEDs will fail, so they can be powered at full power. When a power supply is used for LEDs and fixtures, a certain percentage of the power will be consumed in the process of heating the limiting resistors.

Powering the LEDs from the drivers increases their service life, since in this case the current does not exceed the maximum allowable.

For the driver, you should select LEDs in the right quantity and with the required power, since it is an element specifically designed for a specific current and power. If various consumers are suitable for a conventional PSU, then the use of the driver is limited to LEDs. They are most often used when:

- circuit without resistors (for example, on separate diodes);

- it is not required to periodically disconnect some of the LEDs from them;

- it is possible to independently calculate the required number of LEDs and drivers.

Power supplies are most often used when there are LEDs with built-in resistors, and also if periodic shutdown of some of the LEDs is required. The criteria for choosing a power supply for an LED strip considered in the article will allow you to correctly determine the right device, and tips for connecting it will make this procedure as easy as possible and make it possible without the involvement of specialists.

Давно хочу сделать потолочную светодиодную подсветку на кухне, но не мог понять от чего все таки запитывать. Щас все встало на свои места, статья очень подробная. Спасибо))

отличная статья, теперь знаю какими критериями воспользоваться при выборе блока питания.

Согласен, хорошая статья , мне помогла.

В первый раз я подключал ленту самостоятельно. был у меня какой то трансформатор с клеммами для выбора напряжения и она у меня практически моментально сгорела. От электричества я не то что бы очень далек. но полноценно в нем не разбираюсь. Еще одна лента на лоджии была подключена через блок питания от компьютера. Друг постарался. Нормально работала, с помощью ее украшали лоджию на новый год. А еще одну покупали уже со специальным блоком питания. Кстати, в статье много полезной информации как правильно ленту подключить. Будем знать)))!